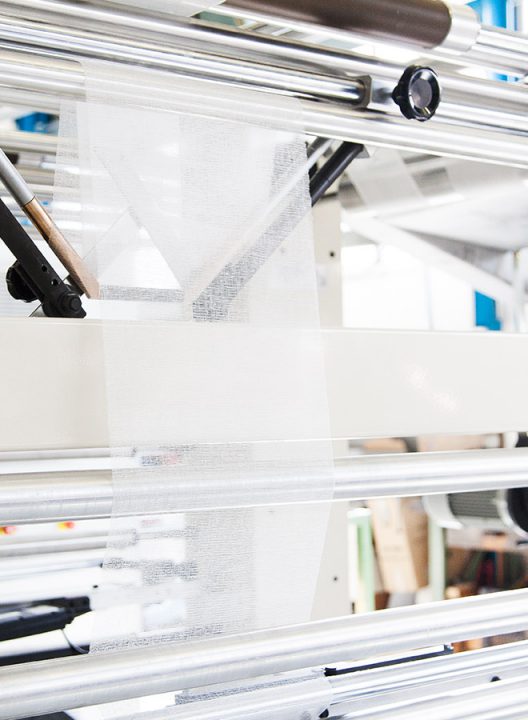

This machine automatically folds cotton gauze compresses and then stacks them in outlet channels where they are counted.

The MCA4 BR450 is available in the multiformat and monoformat models.

| Useful width | 44 cm |

| Number of tracks | Maximum 2 (varies according to the size of compresses) |

| Sizes | Minimum dimension of compresses: |

| Number of plies | 8 – 12 – 16 – 20 – 24 plies |

| Folding | The conventional folding is the 5-fold “Surgical”, or “American” type, with edges and corners tucked-in, however by offsetting folds other combinations are possible. |

| Stacking | Stacking is carried out in the channels where the compresses are counted and ready to be manually inserted into paper bags. |

| Production | Examples of theoretical productions: |

| Options | Barium fixing track by track |

For further information on target machine(s), please use the contact form

Contact usContact usThis machine automatically folds and pack into blister cotton gauze surgical compresses.

It is available in 2 versions:

MCA4-BR450-PACK monoformat (5x5cm)

MCA4-BR450-PACK multiple formats (7,5×7,5cm and 10x10cm)

This fully automatic line can be combined with machines to produce classical cotton gauze compresses (3 folds) or nonwoven compresses.

| Useful width | 45 cm |

| Number of tracks | Maximum 2 (varies according to the size of compresses) |

| Number of plies | 8 – 12 – 16 – 20 – 24 – 28 – 32 plies |

| Folding | The folding is the 4 to 5 fold “Surgical” or “American” type, with edges and corner tucked-in. |

| Control and Packing | By camera and cells before packing operation. |

| Production | Dimension des compresses : |

| Options |

For further information on target machine(s), please use the contact form

Contact usContact usThis machine automatically folds cotton gauze compresses and then stacks them in outlet channels where they are counted.

The MCA4 BR700 is available in the Multiformat and Monoformat models.

| Useful width | 65 cm |

| Number of tracks | Maximum 4 (varies according to the size of compresses) |

| Sizes | Minimum dimensions of compresses: |

| Number of plies | 8 – 12 – 16 – 20 -24 – 28 – 32 plies (according to format) |

| Folding | The conventional folding is the 5-fold “surgical” or “American” type, with edges and corners tucked-in, however by offsetting folds other combinations are possible. |

| Stacking | Stacking is carried out in the channels where the compresses are counted and ready to be manually inserted into paper bags or boxes. |

| Production | Examples of theoretical productions: |

| Options | Barium fixing track by track |

For further information on target machine(s), please use the contact form

Contact usContact usSwab folding machine, folds automatically gauze swabs (The machine is indispensable for the use of the P100).

| Working width | 30 cm |

| Length of cut | Minimum : 15 cm |

| Number of tracks | 3 tracks maximum |

| Possible sizes | Minimum size of swabs: 5 cm x 5 cm |

| Folding | The conventional folding is at 3 plies of the dental type but folds |

| Production | 2 speeds: 1,200 and 1,800 strokes per hour on 3 channels |

| Stacking | Per packets of 5 swabs (optional stacking per packets: 4 or 6 swabs) |

| Discharge | By endless belt, reserve: 20 to 60 swabs |

| Counter of cycles | 5-digit with rapid reset |

| Motor power | 0,37 kW |

| Installed electric power | < 0,6 kVA |

| Net weigth | 210 kg |

For further information on target machine(s), please use the contact form

Contact usContact usThis machine automatically folds cotton gauze compresses and then packs them individually or in groups into sachets.

| Useful width | 44 cm |

| Number of tracks | Minimum dimensions of compresses: |

| Number of plies | 8 – 12 – 16 plies |

| Folding | The conventional folding is of the 3-fold dental type, however the possibility of offsetting of the folds allows for other combinations. |

| Bagging | Cold sealing (pressure on bonding). |

| Production | Examples of theoretical productions: |

| Options | Gauze roll loading by pneumatic cylinders |

For further information on target machine(s), please use the contact form

Contact usContact usThis machine automatically folds non-woven compresses and then packs them individually or in groups into pouches.

| Useful width | 45 cm |

| Number of tracks | Maximum 4 (varies according to the size of compresses and pouches) |

| Sizes | Minimum size of compresses: |

| Number of plies | 2 – 4 – 6 – 8 plies |

| Folding | Cross folding (1 fold) |

| Bagging | Cold sealing (pressure on bonding or knurling). |

| Production | Examples of theoretical productions: |

| Options | Production of sizes bigger than 10 cm x 20 cm |

For further information on target machine(s), please use the contact form

Contact usContact usThe operation consists in winding, and cutting a length of gauze length from 3 m to10 m.

The machine works with a 70 to 140 cm width gauze roll having a diameter of maximum 120 cm.

| Working width | 70 to 140 cm |

| Maximum allowable diameter of roll at the inlet | 120 cm |

| Possible sizes | Diameter of the gauze roll: Min: 20 mm Max: 50 mm |

| Production | Max linear speed: 90 meters/min |

| Installed electric power | < 4 kVA |

| Net weight | 2 200 Kg |

For further information on target machine(s), please use the contact form

Contact usContact usThis machine is designed to slit rolls of gauze into various widths.

The material cut is wound into strips onto cardboard tubes.

Excellent quality strips are obtained by a system of wheels which crush the slit edges.

The selvedges are sucked into a box.

Expanding shafts ensure optimum hold of the rolls.

| Useful width | 160 cm |

| Number of cuts | 10 moving cutters |

| Number of Crushing wheels | 10 mobile wheels |

| Continuously adjustable unwinding speed | 0 to 200 m per minute |

| Maximum allowable diameter of roll at the inlet | 120 cm |

| Maximum diameter of rolled strips | 120 cm |

| Inside diameter of roll cores | 76 mm |

| Motor power | 3 KW |

| Installed electric power | 8 kVA |

| Net weight | 3800 Kg |

| Options | Sewing machine |

For further information on target machine(s), please use the contact form

Contact usContact usWinds, cuts and packs a length of gauze between 3 m to 10 m.

| Working width | 90 to 140 cm |

| Maximum allowable diameter of roll at the inlet | 70 cm |

| Possible sizes | Maximum diameter of the bands: 50 mm |

| Sheathing | Packing into paper sleeve and knurling are carried out automatically during the winding by an independent device. |

| Production | According to chosen length – from 160 to 280 rolls per hour |

| Installed electric power | < 2,8 kVA |

| Net weigth | 720 kg |

For further information on target machine(s), please use the contact form

Contact usContact usCuts gauze strips of variable width – as well as coated fabrics, plastic materials, rubber, paper…

| Working width: | 140 cm |

| Number of cuts | Machine supplied with 6 pairs of moving cutters |

| Minimum cutting width | 40 mm |

| Continuously adjustable unwinding speed | 0 to 60 m per minute |

| Maximum allowable diameter of roll at the inlet | 70 cm |

| Maximum diameter of rolled strips | 60 cm |

| Motor power | 1,5 kW (variable speed) |

| Installed electric power | < 3 kVA |

| Net weigth | 580 kg |

For further information on target machine(s), please use the contact form

Contact usContact usFolds the gauze lengthwise into several plies, and winds for the preparation of swabs.

| Working width | 100 or 130 cm |

| Possibilities of lengthwise folding | 2 to 9 plies |

| Speed continuously adjustable | 0 to 60 m per minute |

| Maximum diameter of the roll at machine inlet | 45 cm |

| Maximum diameter of finished roll | 75 cm |

| Motor power | 1,5 kW (variable speed) |

| Installed electric power | < 3 kVA |

| Net weight | 245 kg or 290 kg |

| Option | Counter

The machine is indispensable for the use of the STD300 |

For further information on target machine(s), please use the contact form

Contact usContact usThermoforming machine model MP400 (applications: industrial blister packaging, medical and pharmaceutical products…)

| Length of machine frame | 2.5 m and 3 m |

| Welding protection | Standard to length, not liftable in plexi |

| Standard width (mm) | 320 / 420 |

| Adjustable min. / maxi. width (mm) | Optional 220 / 420 |

| Maximum depth supple (mm) | 70 / 110 |

| Maximum depth stiff (mm) | 50 (1 deposit) |

| Maximum pitch | 300 on the 3 m / 240 on the 2.5 m |

| Diameter of lower supply | 400 mm aluminium |

| Diameter of upper supply | 300 mm aluminium |

| Use of stiff films | maxi. 600 µ |

| Min. / maxi. pace of supple film (strokes per minute) | 6 to 12 strokes per minute |

| Min. / maxi. pace of stiff film (strokes per minute) | 5 to 8 strokes per minute |

| Length | 3.5 m to 4 m |

| Width | 1.1 m |

| Height | 1.8 m |

| Water consumption | 200 l per hour |

| Electricity consumption | 6 kW |

| Air consumption | 36-40 Nm3 per hour |

For further information on target machine(s), please use the contact form

Contact usContact usThermoforming machine model MP420 (applications: industrial blister packaging, medical and pharmaceutical products…)

| Length of machine frame | from 4 to 7 m maximum |

| Welding protection | As standard plexi (optional stainless steel) |

| Standard width (mm) | No fixed width |

| Adjustable min. / maxi. width (mm) | 220 / 620 |

| Maximum depth supple (mm) | 70 / 110 / 130 |

| Maximum depth stiff (mm) | 70 / 110 / 130 |

| Maximum pitch | 450 (supple) / 400 (stiff) |

| Diameter of lower supply | 500 mm aluminium |

| Diameter of upper supply | 400 mm aluminium |

| Use of stiff films | 600 µ |

| Min. / maxi. pace of supple film (strokes per minute) | 10-17 strokes per minute |

| Min. / maxi. pace of stiff film (strokes per minute) | 10-12 strokes per minute |

| Length | 5 to 8 m |

| Width | 1.1 m / 1.3 m |

| Height | 1.8 m |

| Water consumption | 200 l per hour |

| Electricity consumption | 6-8 kW |

| Air consumption | 50-60 Nm3 per hour |

For further information on target machine(s), please use the contact form

Contact usContact usThermoforming machine model MP440 (applications: industrial blister packaging, medical and pharmaceutical products…)

| Length of machine frame | From 4 m to 12 m (prior study if > 12 m) |

| Welding protection | Stainless steel (sliding, liftable, door…) |

| Standard width (mm) | No fixed width |

| Adjustable min. / maxi. width (mm) | Standard 220 / 620 |

| Maximum depth supple (mm) | 70 / 110 / 130 |

| Maximum depth stiff (mm) | 70 / 110 / 130 |

| Maximum pitch | 800 (supple) / 600 (stiff) |

| Diameter of lower supply | 500 mm stainless steel |

| Diameter of upper supply | 400 mm stainless steel |

| Use of stiff films | 1000 µ (PS) / 800 µ (PVC / APET) |

| Min. / maxi. pace of supple film | 10-17 strokes per minute |

| Min. / maxi. pace of stiff film | 10-15 strokes per minute |

| Length | 5 to 13 m |

| Width | 1.1 m / 1.3 m |

| Height | 1.8 m |

| Water consumption | 200 l per hour |

| Electricity consumption | 8 to 20 kW |

| Air consumption | 50-70 Nm3 per hour |

For further information on target machine(s), please use the contact form

Contact usContact usMachine equipped with:

– Adjustment and control of longitudinal pneumatic sealing pressure,

– Identifcation system for pre-printed paper,

– Touch sensitive screen faciliting changes of sizes,

– Outlet table.

| Packaging material | Cold sealable zoned paper |

| Linear speed | Up to 60 meters per minute |

| Number of cycles | |

| Number of tracks | Up to 350 cycles per minute (according to product and lenght of pouch) |

| Pouches | Width: From 70 to 450 mm |

| Paper roll diameter | 600 mm |

| Type of transmission | By servomoteurs |

| Installed electric power | < 7 kVA |

| Options | Faulty pouch detection / Ejection system (cells or caméras) |

For further information on target machine(s), please use the contact form

Contact usContact usAutomatic folding of nonwoven drapes through following operations:

– Unwinding of the nonwoven fabric,

– Lengthwise folding (2 possible types),

– Detachment of the folded length by means of a rotary cutting,

– Folding of the finished drape (3 possible types),

– Output of the finished product on an out-feed table.

The process is continuous. It includes the automatic control of the product parameters, and allows the storage of product recipes corresponding to drape formats to produce.

| Unwinding | Max width: 1800 mm |

| Folding | Product width at the folding head input: 450 mm maxi |

| Cutting | Cutting accuracy: ± 10 mm |

| Product feature | Maximum size of the unfolded drape: |

| Production | Length 2.75 m: |

| Line speed | 60 meters per minute |

| Overall machine dimensions | Dimensions (in m.): |

For further information on target machine(s), please use the contact form

Contact usContact usThis machine automatically folds wipes and the stacks them in outlet channels where they are counted (industrial, hospitals and household wiping applications).

| Useful width | 40 cm |

| Lenght of cut | Maximum 50 cm |

| Number of tracks | Maximum 4 (varies according to the size of pieces) |

| Sizes | Minimum dimensions : 10 cm x 10 cm |

| Folding | “Z” folding. Other combinations are available on request. |

| Stacking | Stacking is carried out in the channels where the pieces are counted and ready to be manually inserted into paper bags. |

| Production | Examples of theoretical productions: |

For further information on target machine(s), please use the contact form

Contact usContact us